Mastering Welding Electrode Baking: Why Proper Drying and Storage Are Essential

In the world of cricket, the quality of a bat can make or break a player’s performance. One of the most overlooked yet Welding electrodes are at the heart of every successful welding project. However, many welders and manufacturers often overlook a critical aspect of their performance: proper baking and storage. Moisture can have a significant impact on the quality of welding, leading to cracks, porosity, and weaker welds. In this blog, we’ll explore why welding electrode baking is crucial, the ideal baking process, and how industrial ovens designed for this purpose ensure superior results.

Why Welding Electrode Baking is Important

Electrodes, especially low-hydrogen types, are highly sensitive to moisture absorption. Here’s why proper baking is critical:

1. Prevention of Hydrogen Cracking: Moist electrodes can release hydrogen into the weld, causing cracking and compromising structural integrity.

2. Improved Weld Quality: Dry electrodes produce clean, consistent welds with fewer defects.

3. Compliance with Standards: Many welding codes, such as AWS (American Welding Society), require specific electrode baking and storage conditions to ensure safety and quality.

The Electrode Baking Process

Baking is the process of removing absorbed moisture from electrodes before they are used. It typically involves exposing them to high temperatures in a controlled environment.

Ideal Baking Conditions for Welding Electrodes:

Temperature: Baking temperature varies based on the type of electrode. For instance:

Low-hydrogen electrodes (e.g., E7018): 250-450°C (480-840°F) for 1-2 hours.

General-purpose electrodes: 150-200°C (300-400°F) for 1-2 hours.

Duration: Follow the manufacturer’s guidelines for optimal results.

Cooling: After baking, electrodes should cool gradually to avoid rapid temperature changes that can cause damage.

Why Industrial Baking Ovens Are Essential

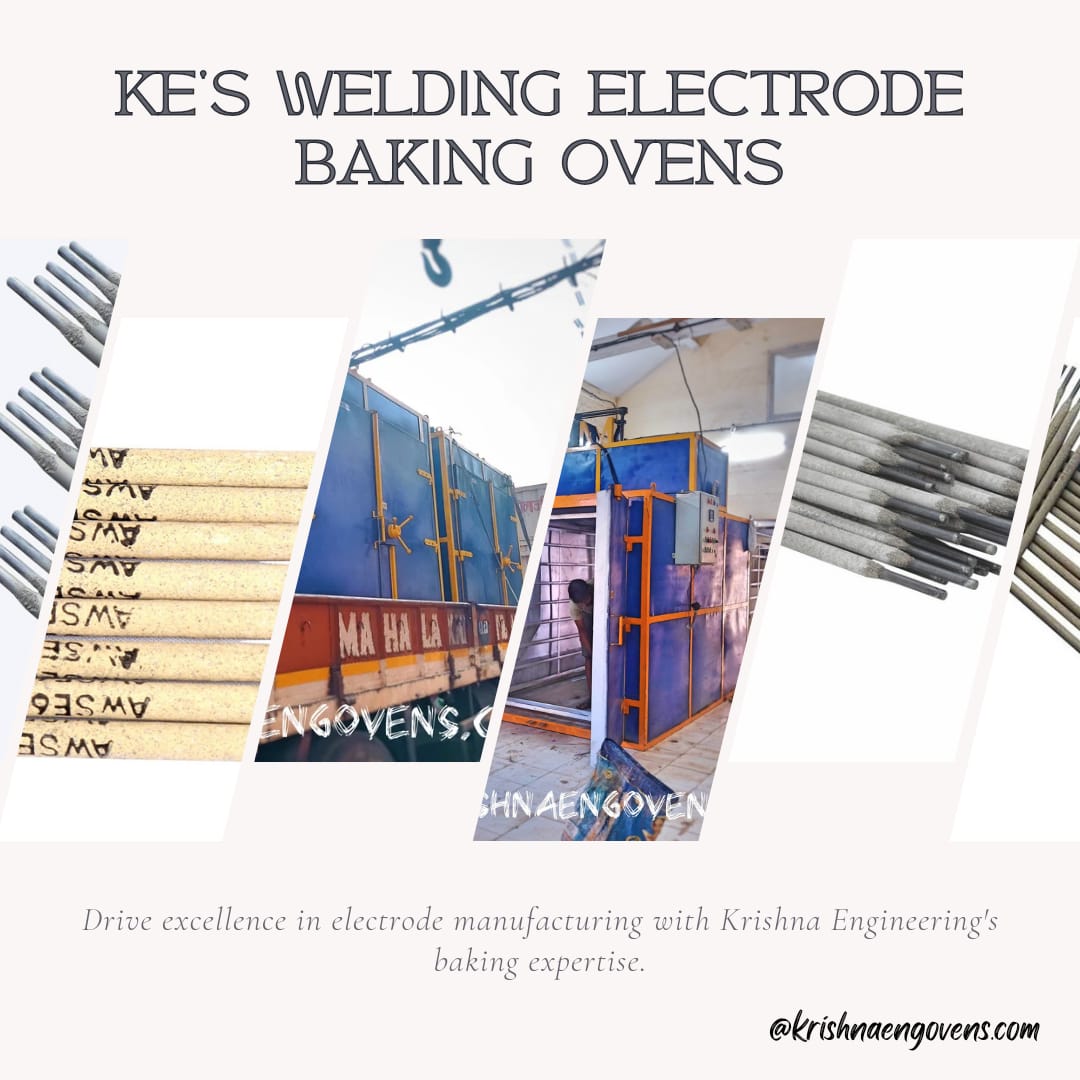

While traditional methods like open flames or makeshift ovens might work for small-scale applications, industrial ovens are the gold standard for electrode baking due to their precision and efficiency.

Key Features of Industrial Baking Ovens

1. Uniform Heat Distribution: Ensures that all electrodes in the batch are baked evenly.

2. Temperature Control: Precise temperature settings prevent overheating or underheating.

3. Energy Efficiency: Modern ovens, like those from Krishna Engineering, are designed to minimize energy consumption while maintaining optimal performance.

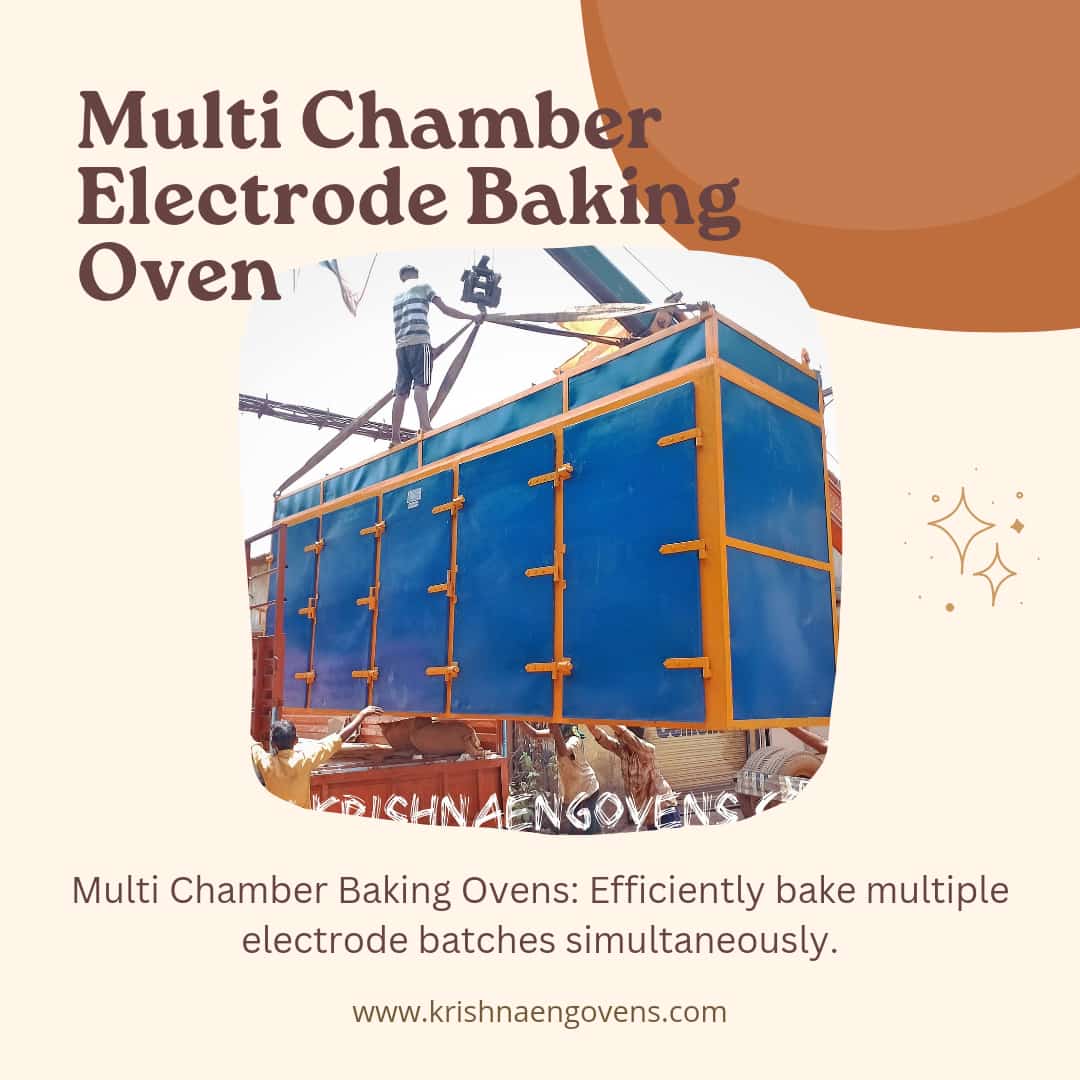

4. Capacity and Customization: Industrial ovens can handle large batches and are customizable to fit specific production requirements.

Common Mistakes to Avoid During Electrode Baking

1. Overbaking: Can cause the flux coating to become brittle, reducing electrode usability.

2. Using Incorrect Temperatures: Leads to uneven drying and compromised performance.

3. Skipping Storage Procedures: Baking is only effective if the electrodes are stored in dry, humidity-controlled environments afterward.

How Krishna Engineering Ovens Revolutionize Electrode Baking

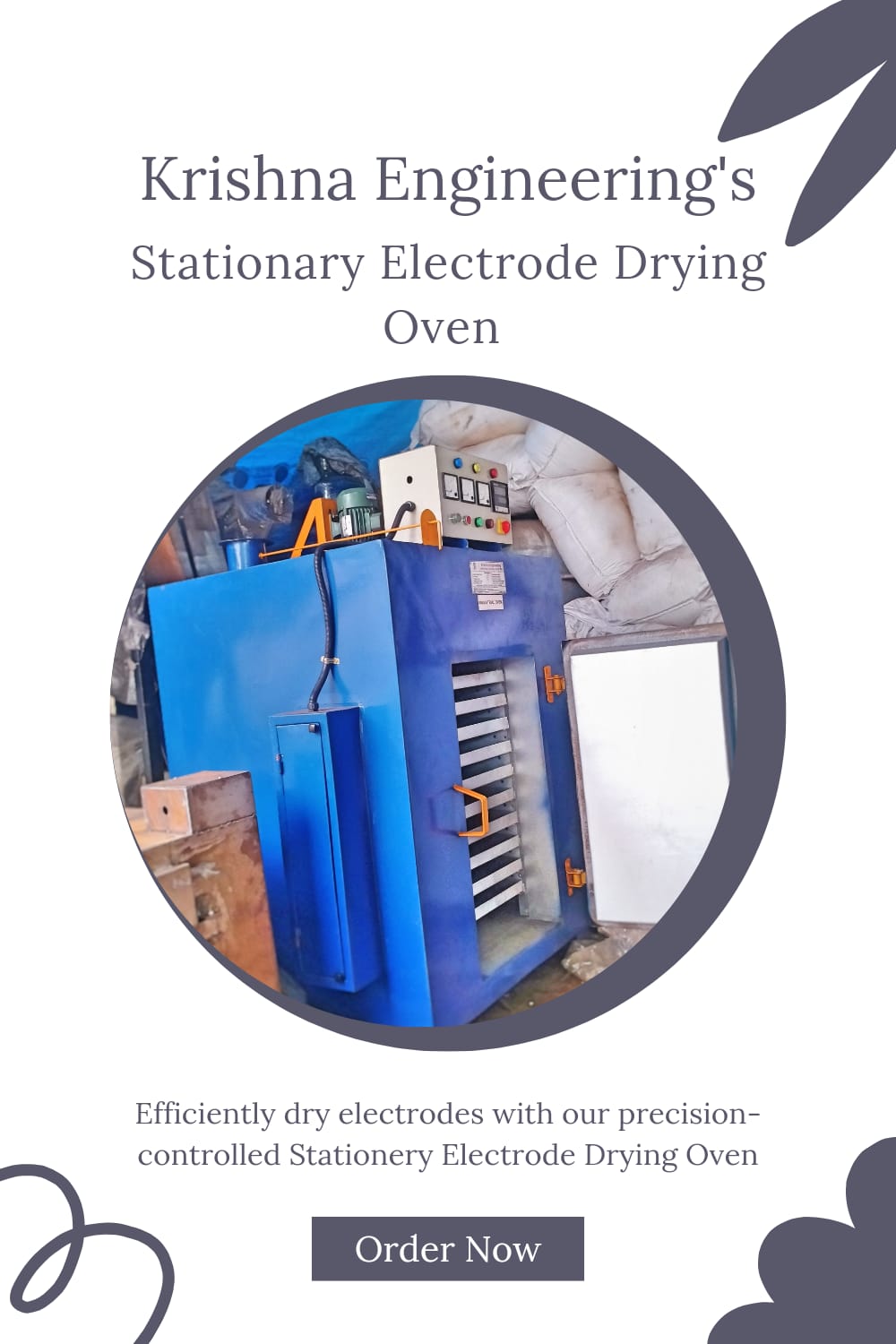

Krishna Engineering specializes in manufacturing state-of-the-art industrial ovens tailored for electrode baking. Our ovens come equipped with:

1. Advanced insulation for energy efficiency.

2. Customizable shelves to accommodate various electrode sizes.

3. Digital controls for precise temperature and time management.

Conclusion

Proper baking and storage of welding electrodes are non-negotiable for achieving high-quality welds and adhering to industry standards. Industrial baking ovens are the perfect solution for ensuring precise, efficient, and consistent baking. If you’re a welding electrode manufacturer or welding professional looking to optimize your baking process, Krishna Engineering has the perfect solution for you. Contact us today to learn how our advanced ovens can elevate your operations and deliver unmatched results.